Determining the appropriate land area for an LNG (Liquefied Natural Gas) station is a critical step during the preliminary design phase. The required area depends on the station’s capacity, equipment configuration, and safety operation standards. Below are commonly applied calculation principles:

1. Determine Gas Consumption Capacity

The LNG station is designed based on the gas consumption demand, typically measured in Nm³/h or tons/day. This capacity determines the number of storage tanks, regasification units, and the scale of auxiliary systems.

Example: A station supplying a factory with a demand of 10,000 Nm³/day.

2. Key Components of the Station Area

a) Construction Zone

- Foundation & equipment layout: Includes LNG storage tanks, regasification units, and loading/unloading points.

- Spill containment & drainage: Designed in compliance with fire safety standards.

- Fencing & safety corridors: Ensures isolation and safety per regulations.

b) Mechanical & Equipment Zone

- LNG storage tanks: Typically 1–2 tanks of 20–60 m³ each, occupying 30–60 m² per tank (excluding safety distances).

- Regasification & control systems: Around 15–30 m².

- Truck loading area & process piping: Approximately 30–50 m².

- Power station & heating systems: 20–40 m², depending on configuration.

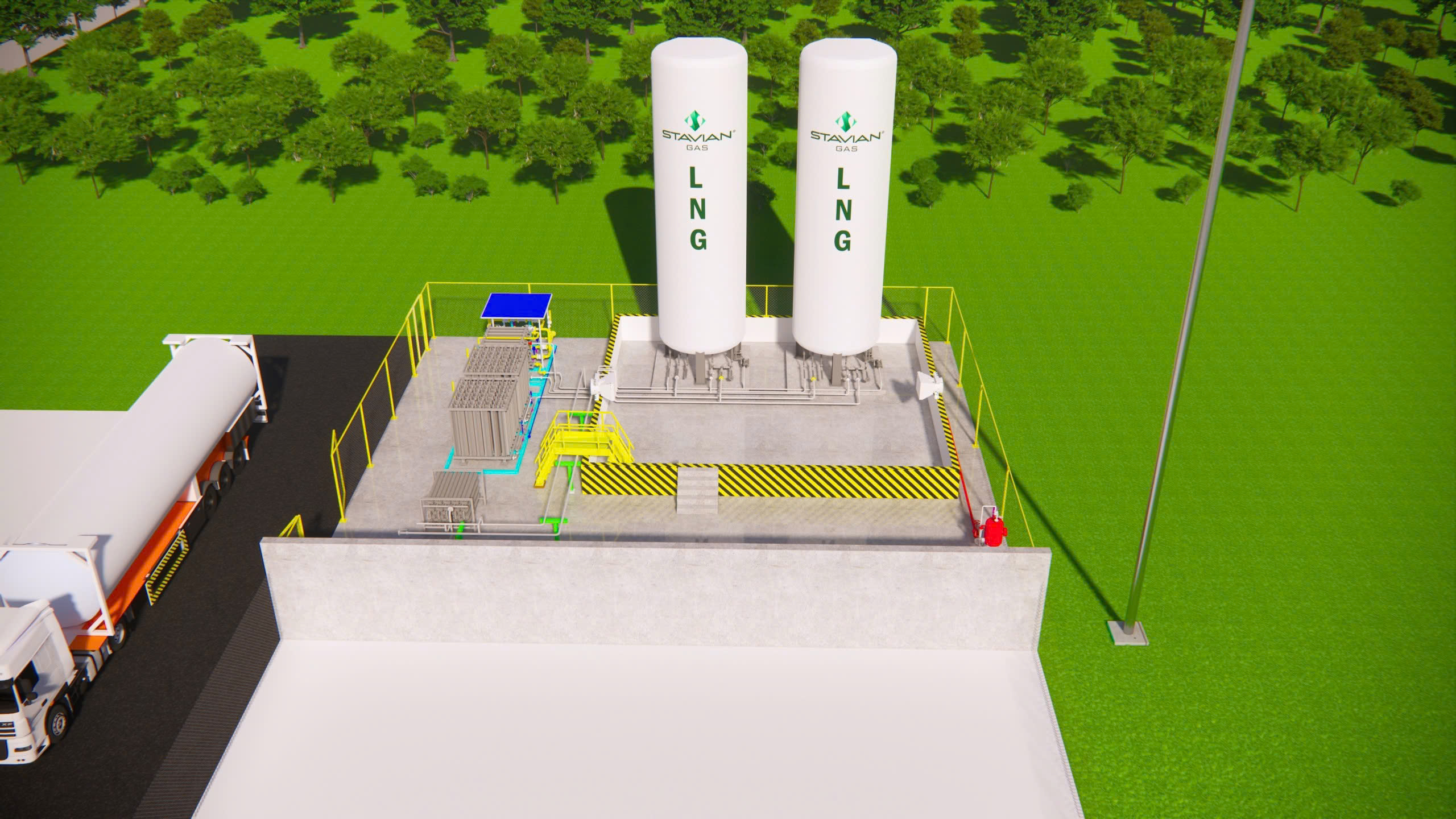

(Image: An LNG station by Stavian Gas Joint Stock Company)

3. Reference Area by Capacity

| Gas Consumption Capacity | Estimated Station Area |

| < 5,000 Nm³/day | ~250 – 300 m² |

| 5,000 – 10,000 Nm³/day | ~400 – 600 m² |

| > 10,000 Nm³/day | 700 m² and above |

Note: The above dimensions do not include mandatory fire safety distances. In actual design, the total area will be larger to meet isolation, firefighting, and operational safety requirements.

Each project has unique site conditions and technical requirements. Please contact our experienced engineering team for tailored and optimized LNG station design solutions.

Hotline: +84 968 756 443