An LNG (Liquefied Natural Gas) storage tank used in gas supply stations is a vacuum-insulated cryogenic tank, specifically designed to store natural gas in liquid form at extremely low temperatures (-162°C). Below are the key features:

1. Common Types of LNG Storage Tanks

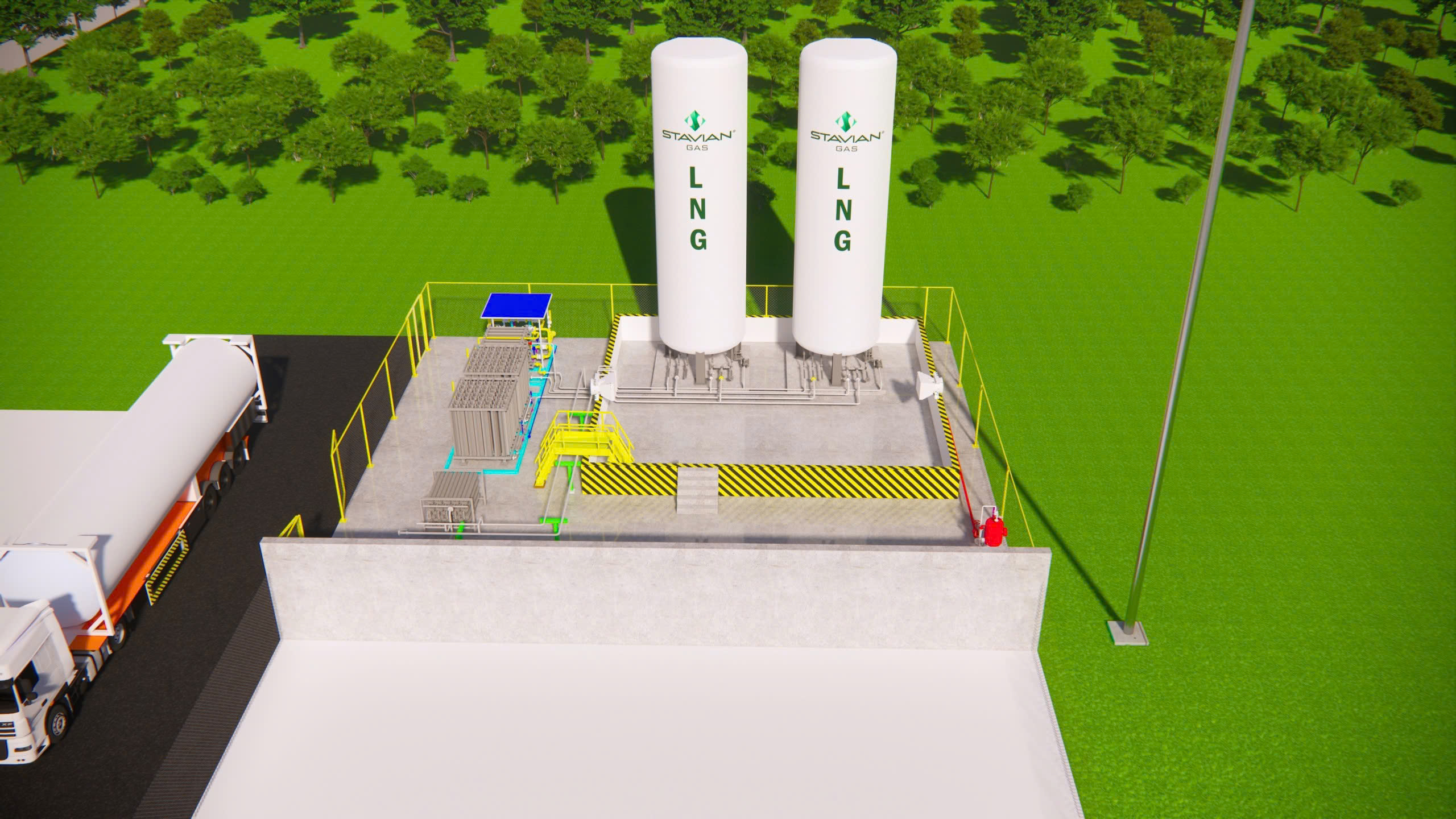

Vertical Vacuum Insulated Tank

This is the most commonly used tank type for industrial LNG stations. It consists of:

- Inner vessel: Made of stainless steel (304/316L), designed to hold LNG at -162°C.

- Outer vessel: Made of carbon steel, designed to withstand the pressure of LNG vapor.

- Vacuum space: The gap between the two layers is vacuumed and filled with insulation material (e.g., perlite) to minimize heat transfer.

2. Capacity and Working Pressure

| Common Volume | Design Pressure | Notes |

| 5 m³ – 60 m³ | ~0.6 – 1.6 MPa | Depends on gas supply demand and storage duration |

| > 60 m³ | Typically used for centralized stations or source stations |

Tank capacity typically ranges from 20 to 60 m³, with working pressures depending on system design and application requirements.

3. Design Standards for LNG Tanks

LNG tanks are designed and manufactured according to strict international standards, such as:

- ASME Section VIII, Division 1/2 – Pressure vessel design and fabrication

- EN 13458 – Cryogenic vessels for liquefied gases

- ISO 21009-1 – Vacuum-insulated cryogenic equipment

4. Installation and Placement

- Tanks are usually installed outdoors on a reinforced concrete foundation.

- Must comply with fire safety distances from buildings, fences, power stations, etc.

- Can be equipped with level sensors, pressure sensors, and integrated safety valves.

5. How is an LNG Tank Different from an LPG Tank?

Although both are used to store liquefied gases, LNG and LPG tanks differ significantly in terms of:

- Design and materials

- Operating temperature and pressure

- Insulation requirements

| Criteria | LNG Tank | LPG Tank |

| Storage Temperature | ~ -162°C (cryogenic) | ~ -20°C to 0°C |

| Design Pressure | 0.6 – 1.6 MPa | 1.6 – 2.5 MPa |

| Insulation | Double-layer vacuum insulation | Simple insulation layer |

| Inner Layer Material | Stainless steel (Inox 304/316L) | Carbon steel |

| Structure | Requires vacuum pumping, perlite or multilayer | No vacuum pumping required |

| Investment Cost | Higher | Lower |

| Applications | Industrial (power generation, heating, etc.) | Residential, commercial, light industrial |

6. Conclusion

- LNG tanks are more technically advanced than LPG tanks, especially in terms of insulation and design standards.

- Due to the cryogenic nature of LNG, these tanks must be double-walled with vacuum insulation and specialized materials to ensure safe and efficient storage.

If your business is considering switching between LPG and LNG, please contact us for expert consultation on the most cost-effective, technically sound, and operationally efficient solution for your specific application.

Hotline: +84 968 756 443